Ultrasonic Impact Treatment (UIT)

What is UIT?

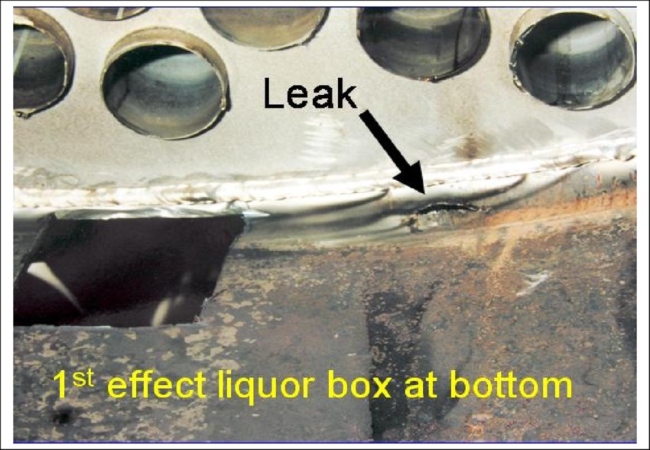

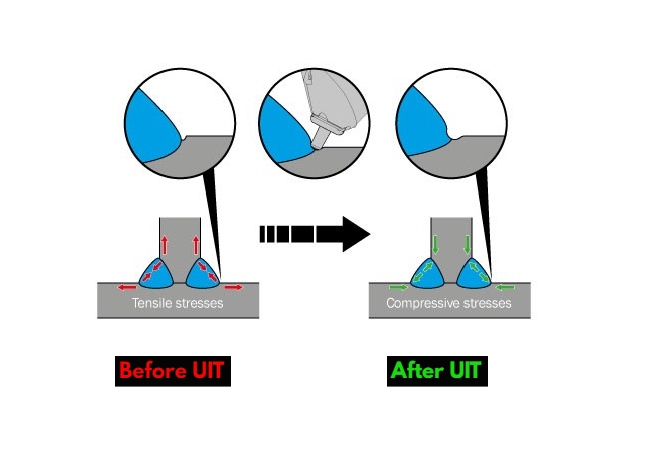

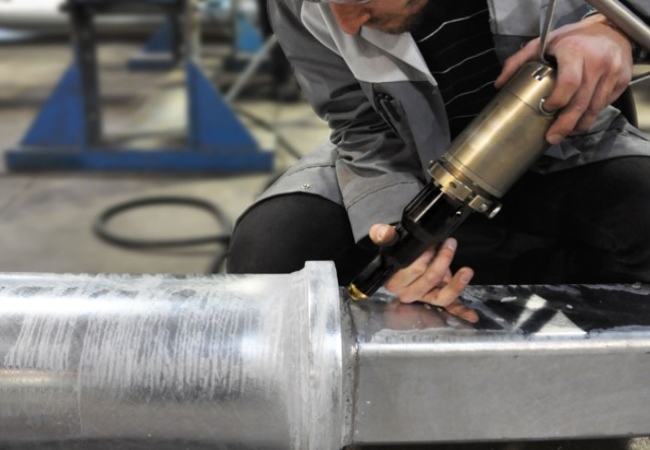

Ultrasonic Impact Treatment is a cold working process, which induces compression on the surface of welded elements and structures, with the help of special ultrasonic strikes, to improve the fatigue life. Ultrasonic impact treatment works on the combine effects of followings:

1. High frequency impacts of the special strikers

2. Ultrasonic oscillation in treated material

WHY UIT?

Ultrasonic Impact Treatment is a relatively new and promising technique for fatigue life improvement that could be efficiently used for rehabilitation and repair of welded elements and structures.

The application of Ultrasonic Peening for treatment of welded elements of existing structures provides, practically, the same increase in fatigue life of welded elements that could be achieved by treatment after/during construction.

The results of fatigue testing of large-scale specimens showed that the welding and subsequent application of Ultrasonic Peening provides the highest endurance of specimens with fatigue cracks as compared with other considered techniques for fatigue life improvement.

The modern equipment for Ultrasonic Penning could be efficiently applied for rehabilitation and repair of welded elements of highway and railway bridges and other areas.

Previous

Next

Schematic view of fatigue life improvement by UIT

[wptb id=1587]

UIT Is The Most Efficient Fatigue Life Improvement Method

Series 1 – as welded

Series 2 – UIT treated , 5 and 3 mm pin diameter

Series 3 – hammer peened

Series 4 – shot peened

Series 5 – TIG dressed

Series 6 – TIG dressed and UIT treated

Series 7 – UIT treated , additional series, 3mm pin diameter

Benefits!

- Increases the fatigue strength by 60-180%

- Increases the fatigue life up to 4-6 times

- Relieves the harmful tensile residual stresses

- Introduces beneficial compressive residual stresses

- Strengthen the weldment

- Closes the micro flaws on surface and sub-surface

- Increases the resistant against stress corrosion cracking(SCC)

- High (highest) efficiency

- Low power consumption

- Quick (treatment speed of ~ 0.5 m of weld/min)

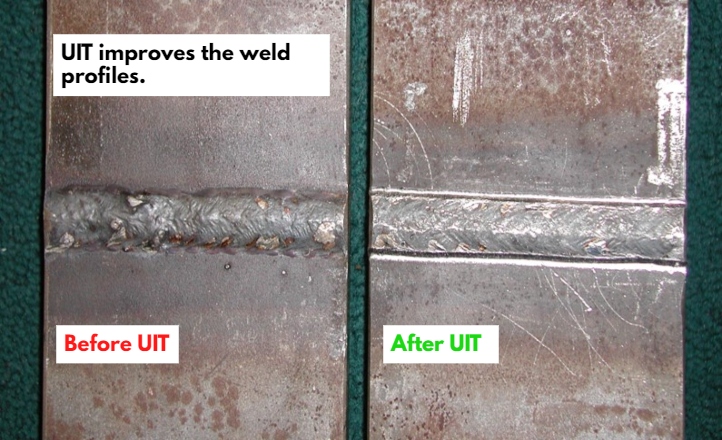

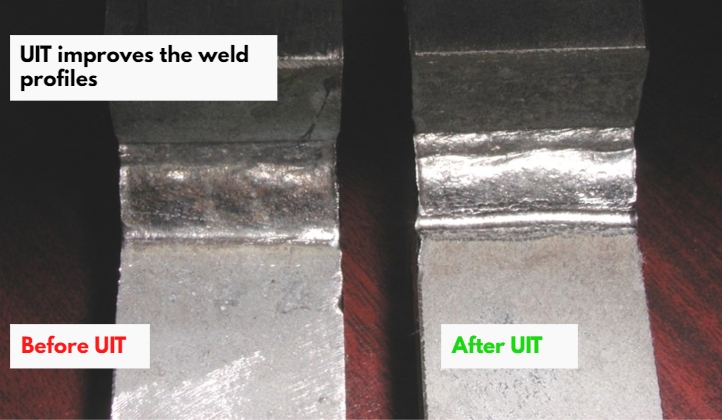

- Improve the weld profile

- Reduce the weld distortion

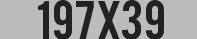

Areas of Applications

- Railways

- Highways Bridges

- Oil & Gas

- Construction Equipment

- Shipbuilding

- Mining

- Automotive

- Aerospace

- Defense

- Industrial Equipment